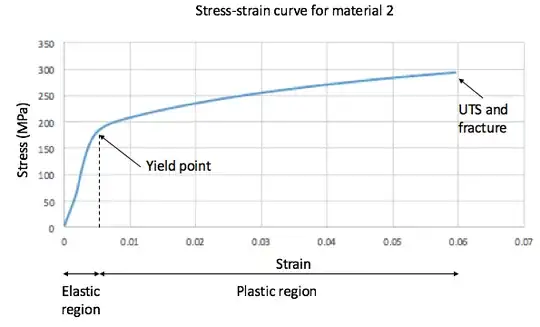

This stress-strain curve presents a linear elastic range, followed by yielding and accompanied by a decrease in toughness the material goes into the plastic region. As it strains more and more the material then suddenly snaps! Without necking...

Fracture occurring without necking isn't something I would expect from a ductile material, in fact it's a trait of a brittle material. But, the material can't be brittle with all that strain in the plastic region.

So which is it? Question: Would this material fall into a "mostly ductile" category instead of ductile?

I have four stress-strain curves i am working with at the moment. Three of them are similar to this one however, they show a decline in stress when necking before fracture. This diagram does not decline in stress before fracture. They were all tested on the same tensile stress machine (a Shimadzu machine i believe). Part of the assessment is to determine the possible types of materials each curve could be.

Question: Because this material doesn't neck so i'm wondering if there are any materials which have a stress-strain curve such as this. I was thinking some metals may strain and then just snap or perhaps timber. I'm really not sure.