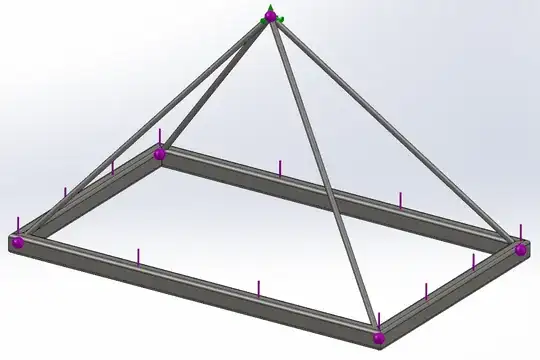

I have a seemingly simple structure and I need to perform a hand calculation to check that the stresses in the members are below the allowable values. In its simplest form, the structure is a rectangular frame made from rectangular tube welded at the corners and suspended from four equal length cables attached at the corners. The cables meet above the center of the rectangular frame and attach to a hook.

For loading purposes, each member of the frame can be considered to have the same uniformly distributed load along its entire length.

So, it looks something like this:

I have been poring over static, mechanics, structural analysis and other books and resources trying to find the methodology for analyzing this but all of these resources seem to stop at planar structures where the loading is in the plane of the structure. Either this is a difficult problem, I am overthinking things, or I have been out of practice with respect to statics for too long.

I have been poring over static, mechanics, structural analysis and other books and resources trying to find the methodology for analyzing this but all of these resources seem to stop at planar structures where the loading is in the plane of the structure. Either this is a difficult problem, I am overthinking things, or I have been out of practice with respect to statics for too long.

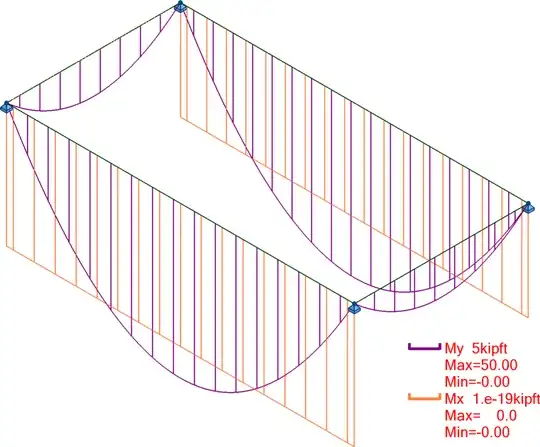

What I have so far is a free body diagram where I have replaced each cable with a spherical moveable support (the 3D equivalent of a roller support). Each corner is free to rotate in all three directions and to translate in the plane of the frame but not out of it. So there is a single vertical reaction force at each corner (which is actually the vertical component of the cable tension). This is an assumption. Please let me know if I am wrong.

The degree of static indeterminancy is $(6m + R) - 6j$, where $m$ is the member count, $j$ is the joint count and $R$ is the number of unknown reaction forces. Plugging in the values leads to an answer of 4. However, I think I can actually reduce that to 1 since (due to symmetry) the reaction force at each corner is identical.

And this is where I am stuck. What is the next step? Or is this the point at which people say "let the computer solve it".