How come axial compressors always narrow and turbines always widen towards the rear? From what I know:

- The speed of sound of air increases with temperature, therefore increases (decreases) as it goes through the compressor (turbine).

- The compressor and turbine blades at each stage should be meeting the air at just below the local speed of sound (more precisely critical Mach number).

- The rotational speed of all stages of a given spool is constant.

- The cross-section through which the air is flowing is $\pi(r_e^2-r_i^2)$, where $r_e$ and $r_i$ are the exterior and interior radii, respectively.

So shouldn't compressors widen and turbines narrow towards the rear, with the interior varying more than the exterior? And shouldn't turbines be much larger (~2x) than the compressors they drive?

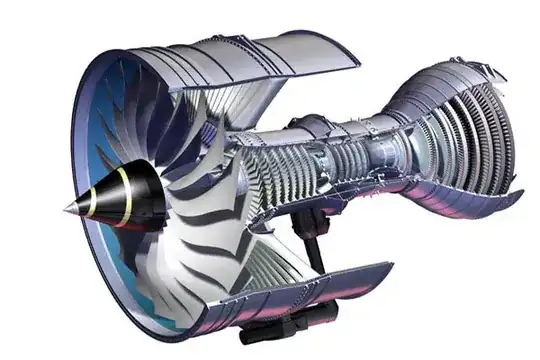

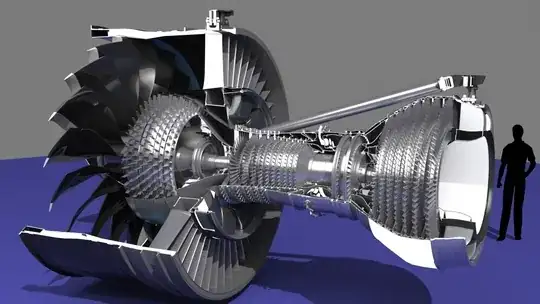

You can obviously see civil engines don't look like this:

RR Trent 1000 (Courtesy of aviationgazette)

GE GEnX (Courtesy of www.mikejamesmedia.com)

Anything I'm not taking, or taking too much, into account in my analysis?