Hy everyone, new here, I don't know much about how high pressure water pumping works - ( i'm just a programmer ) but i need to know if we can create water pressures above 100 000 psi for a crazy water-jet cutting project i have in mind :)

What's the maximum pressure we can reach inside a single pump / or by connecting pumps in series or parallel?

I would like to go to pressures of 500 000 psi or even higher if possible. I have no practical intuition of what that actually means :)

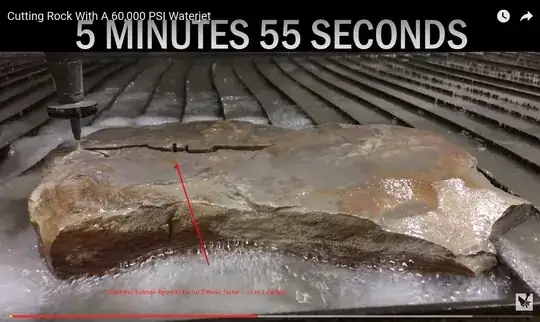

But i know that the higher the pressure the better - my reasoning is - if it takes 5 minutes to cut a big thick block of iron at 100 000 psi- will take 1 minute with 5 times that pressure - ( assume that the other parameters will be scaling as well.)

Taken from here:

At pressures of 60,000 PSI (4,100 bar) and higher, metal fatigue becomes a serious issue with many components. Although pumps that can reach 100,000 PSI have been around for many years, nobody runs them at such pressures because of the extreme maintenance issues involved. For this reason, most manufacturers purposely limit their pumps to below 60,000 PSI (4,100 bar).

This sounds serious - but i'm not too concerned about efficiency here.

I'm interested to know more about the theoretical limits that exist with creating such pressures.. not so much if a pump doing this is available or not for commercial purposes.

What i have in mind is suppose to be a very serious industrial machinery - custom build - all it matters is to cut as fast as possible. All the other concerns like cost or metal-fatigue are secondary.

And also can you please help me picture how big the dimensions of this pump / system of pumps will actually be? What volume it needs to take?

Thanks so much :) Have a nice day!

EDIT 1:

Form @alephzero and @Solar Mike comments (thank you both) i realized there is an important difference between the pressure and the flow rate. This is an xy question and my question title is bad.. sorry about that.

The bottom line is - i need this machine to cut faster - as faster as it can get. I don't think we reached the limits of what's possible with our water jet cutting technologies - and if we did, i want to understand why?

So what are the parameters we need to change - for this cut to happen 5 times faster? Or 10 times faster - or whatever i pick. When we will reach the maximum theoretical and then the practical limit of that this pumps can do.

It will help if we put pumps in series or parallel? It will help if we increase the pressure? Or the flow rate? (but how to increase the flow rate - if the diameter is fixed)

I thought that by increasing the pressure we can make the cut faster. @Solar Mike comment made me realize that i don't need pressure - i need a 5 times higher flow rate - in order to cut 5 times faster. But because the orifice is a certain diameter - i think we can't do it without increasing the pressure.(maybe i'm wrong about this.)

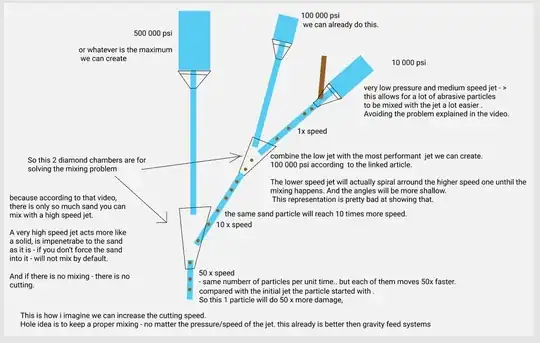

And for now don't worry about how the sand will be mixed with this higher speed jet. Based on this video it seems you can't mix sand if the water jet is at higher speed/ orifice is smaller - but i think i can get around that by combining more water jets into a single one inside a diamond chamber, like this:

Not sure if this schematic will mess up the jet shape - but anyway the first problem is to figure out how to get that jet moving faster. Then we worry about how to add sand to it.

Not sure if this schematic will mess up the jet shape - but anyway the first problem is to figure out how to get that jet moving faster. Then we worry about how to add sand to it.

EDIT 2:

Based on @Mark answer (thank you) i understand now that is not even possible to build such a pump - because the the maximum pressure we can possibly have is 150 000 psi - if that pump is made out of titanium.

There is no material stronger than that - except diamond, graphene and such - which are not an option. (I found a company that makes nozzles out of pure diamond, specially designed for water-jet cutting - but they don't make any pumps :)) - and for sure what @alephzero said about diamond strengths depends on the angle that force acts on it - applies here. )

Just to keep things simple let's stay with 100 000 psi for now. (such a bummer ..)

I still want to cut faster. What can i do?

If cutting faster is related to flow rate - then i need to increase flow rate somehow.

It follows that the only way to do that - is to increase the orifice diameter. (the other way - is to increase the pressure - which is not an option)

If i double the diameter - and increase the power appropriately - that will quadruple the flow rate.

Now because the diameter is double - the water-jet cross section has quadrupled - the amount of material i need to cut out has quadrupled also - the same as with flow rate. (not 100% sure about this - but is my first intuition)

What i'm trying to understand now is: So what will happen to cutting speed by increasing the diameter - is this a zero-sum game ??

I mean, trying to increase speed -> i increase the flow rate -> by increasing the diameter -> which which increases the jet cross section-> which then increases the amount of material i need to cut -> which lowers the cutting speed all over again. So i go nowhere with this?

Or can be beneficial to increase the diameter? My intuition can't confirm anything here- i need someone to help me understand what will happen in the case i increase the diameter.

Is there a way to get out positive form this situation? Or is a hard theoretical limit like the one with pressure?

I rely don't like increasing the diameter - but seems we are out of options here - that's kind of sad..

Thanks everyone, this question got out of hand here - but promise i will not ask more questions :)