While considering this recent question, I started wondering how to determine the strength of the welds in the steel mesh. As AndyT points out in his comment:

The welds at the connections are only intended to keep the bars at right angles during handling - they are not intended to take any load.

The intent of the manufacturer, of course, doesn't stop someone from using the product to support a load anyway. Just what sort of load can this type of weld support? What is/are the likely failure mode(s)?

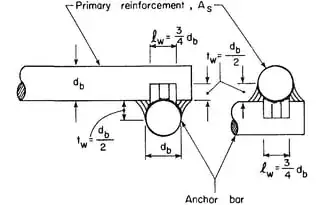

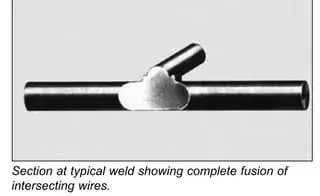

This weld has different geometry and loading than fillet welds (which are the only type I'm at all familiar with). I think it's properly called a flare-v groove weld, though most of the examples I can find show that as joining a round bar to a flat bar or plate. The geometry is different enough that I suspect those are not equivalent, from a design standpoint.

This AWS technical manual says:

2.3.3.2 Effective Weld Size (Flare Groove). The effective weld size for flare groove welds when filled flush to the surface of a round bar, a 90° bend in a formed section, or a rectangular tube shall be as shown in Table 2.1, except as permitted by 4.10.5.

Table 2.1 indicates the effective weld size is either 1/2 or 3/8 the radius of the outside surface of the weld. I'm still not sure this applies to the crossed bars geometry, though.

When I was learning about fillet welds, it was always assumed the weld would fail first in shear along its throat. Given that a square mesh has no cross-bracing and there is a single point of contact between the members (rather than a line or plane of contact), can I afford to make that assumption?

Especially in the case where there are only two rods rather than a mesh grid, this weld could be loaded in quite the variety of configurations. Let's consider only the cases of pure torsion, pure tension and pure shear. Assume the weld fails before the members.