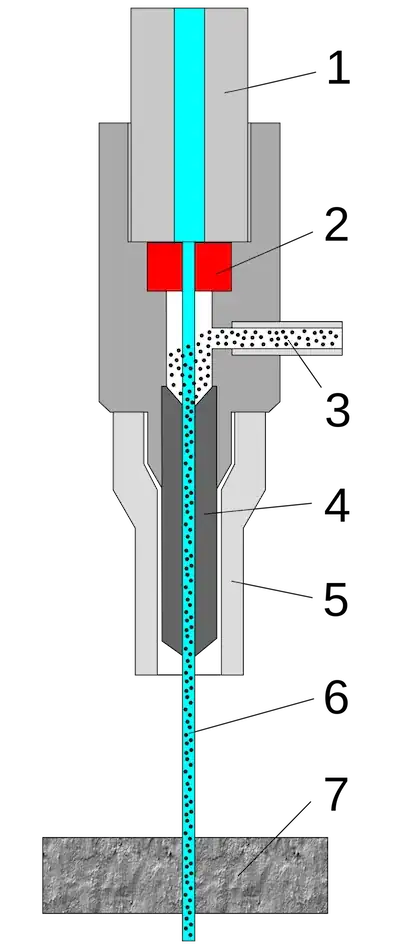

Here is a schematic cross-section of a water jet cutter nozzle design:

As it is shown, the thin water jet grabs abrasive particles in the mixing chamber and the mix flows through the nozzle.

My question is: what makes the water flow through the nozzle despite the loss of kinetic energy due to the abrasive material and the friction inside the nozzle instead of filling up the mixing chamber and running up in the ambient pressured abrasive feeding tube?