A friend of mine that doesn't use the internet much runs a commercial laundry. They use an old 'Manlove Tullis' laundry calendar (c. 1980) that looks like this:

(click to enlarge photos)

Essentially, it is a machine with 3 rollers (2 visible in the photo) on a hot plate. Garments (e.g. bedsheets) go in wet, and come out ironed flat, and dry.

The hot bed runs on steam fed by 6 pipes (2 for each roller) underneath the machine, coming from a big boiler.

A couple of days ago 1 of the pipes broke off/burst under the machine with wear & tear over the years; where the pipe is joined by a coupling to the hot bed.

It is possible that over the years with repeated super-heating and cooling some metal fatigue has crept in, or it became so brittle that it finally failed.

After allowing the machine and the pipes to cool down for a day, he went under the machine to try to fix it; but the pipe is seized to the [possibly brass] coupling. The coupling affixes to the hot bed and it appears it cannot be removed because it is both seized and in an inaccessible part of the machine. It is a 22mm coupling.

The pipe is steel, and could be cut off and a new one joined by welding it or something.

Underneath the machine, the working area is only 50cm in height at most, and it is 10ft x 15ft / 3m x 5m.

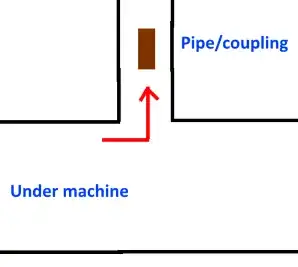

From how it's been explained to me, when you're under the machine lying on the floor; the actual pipe/coupling that needs removing is within a small cavity above you. Something like this:

The space is very limited and the angle very awkward; there are also some health & safety issues with operating a welding torch under there.

An additional coupling could be added, but this introduces another mode of failure.

He has just installed a copper stop end, temporarily, so that he can use the machine with 2 out of 3 rollers operating at 100% and 1 operating at 50%.

The boiler operates at 8 Bar / 115 PSI — therefore the laundry calendar also operates at 115 PSI. From reading online I understand that the pipework is more than adequate. It is also regularly inspected and serviced.

My question is:

How can we get this pipe and/or coupling off and a new one on?

The person I'm posting this question for is very knowledgeable on the subject, but for the first time I've seen, he's stuck here. Three engineers have been out on-site and don't know what to do.

One has said that "it either needs to be welded or a proper coupling added; but it cannot be cut off because it is inaccessible".