I have a 2 mm thick high-quality carbon fiber composite sheet. I want to cut a shape in it with a 0.8 mm diamond flute end mill. I need a cut this narrow because of the shape's detail. The shape's total cutting length is about 30 cm, cut depth 2.1 mm (three passes of 0.7 cut depth). The plate is glued to a solid plastic base and pressed with several clamps, then submerged in water.

The mill end breaks after about 10 cm (HSS) to 40 cm (tungsten carbide). Current mill parameters are 40 mm/min, cut depth 0.7 mm, 10 000 rpm, but I tried anything starting at 10 mm/min. Does not seem to change a lot.

The CNC is 3018 upgraded with a 500 W 10 000 rpm brushless DC motor. When looking at a rotating end mill, no soft edges are seen in hard light (there is instead an illusion that the mill is not rotating at all) so I think that the spindle's vibration is low. But anyway, I changed the spindle to a small brushless DC 20 000 rpm and tried it at rpm from 8 000 to 20 000. Same thing, the end mill breaks after some dozen cm.

A 3018 CNC is not top quality for sure, but it seems to work smoothly. It is controlled with upgraded electronics - drivers are TMC2209, firmware is GRBL. Maybe there is a ~0.1 mm backlash when looking at a circular cutout, but I'd guess that a backlash is something which may pause the spindle's XY for a moment, not something which jerks it, at least not at only ~ 30 mm/min.

I had never problems with this machine when using end mills of diameters >= 2 mm (can't say about diameters > 0.8 mm, < 2.0 mm because I have never used them). Also, the said 0.8 mm end mills do not have any problems with a very hard maple wood.

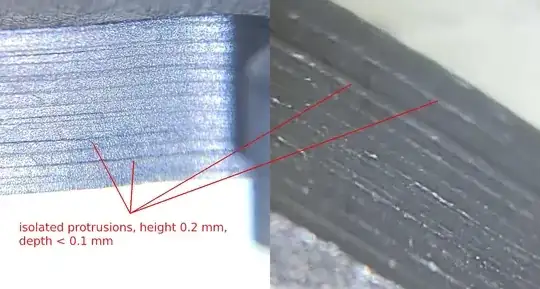

This microscopic photo shows an average quality of the cut, pass depth 0.7 mm:

Spindle power consumption at 15 000 rpm, 0.4 mm cut depth as suggested by fred_dot_u:

- free: 17.3 W

- isolated groove 0.4 mm deep: 18.2 W

- isolated groove 1.6 mm deep: 18.7 W

- adjacent groove 1.6 mm deep: 18.3 W

Any ideas? Is it really that hard to cut a carbon fiber plate with a sub-mm end mill or something is wrong here?