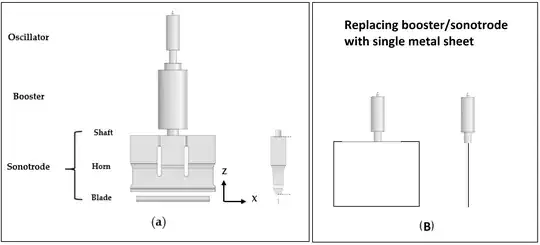

I want to make an ultrasonic cutter for home use projects, something like this or there are many online videos of industrial ultrasonic cutters in e.g. the food industry. A typical design of an ultrasonic cutter is below on the left (a). It has a booster (a shaped metal cylinder whose length has been tuned to match the resonance of the oscillator), and then a sonotrode (to do the same thing I believe). The sonotrode has a particular profile of its own.

What is the purpose of the wedge shape of the sonotrode profile and the slots?

If I replace both with a single flat sheet of metal (as in (b)), tuned to the resonance of the oscillator as will the professional version be - what will I lose in terms of performance from the professional version?