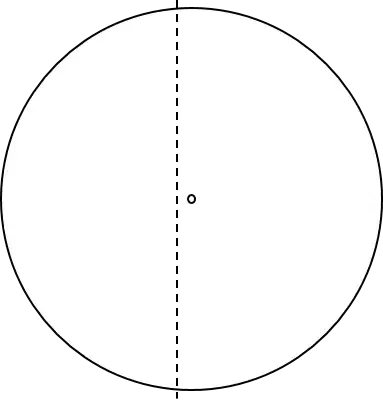

I have a circular puck of stainless steel that is 9.5 mm in diameter. In the center, there is already a 5 um pinhole. My objective is to basically cut the steel along the dotted line, approximately 0.5 mm from the pinhole. Can you advise on what techniques to can make this cut precisely?

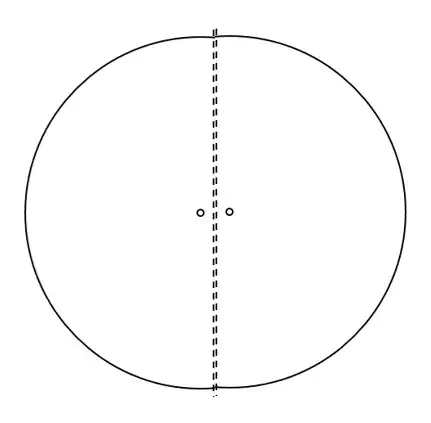

The reason I want to do this is to be able to align two of these so that I can have 2 pinholes that are ~1 mm apart from one another, as in the following image.